User Guide

Inflation!

The flexible all-plastic Polyform valve is fitted into every inflatable Polyform product.

The V-10 valve is a non-return type of valve, fitted with a protective valve screw. For inflation, the screw has to be removed. Air is blown into the valve, and the valve screw has to be set back in place in order to fully secure any loss of air from the valve. The valve is equipped with a non-return flap that secures the air when inflating.

The V-40 valve is designed for easy inflation and deflation of our largest products. This is not a non-return valve. To inflate the product, the valve is opened by turning the valve screw anti-clockwise 3-4 times (do not remove the screw). Inflate through the center hole of the screw itself, and tighten the screw.

To inflate you can use a hand pump, but preferably an air compressor with a blowgun or - if you have a Polyform inflation adapter - with a tire nozzle.

The products are designed to be inflated to 0.15 to 0.20 bar of pressure at 20° celsius.

NOTE: For use under tropical conditions / high temperatures (also consider even dark colored products exposed to strong sunlight) the pressure should to be reduced down to 0.05 - 0.06 bar. Also always consider the diameter of the product and that you are able to depress the walls.

Also consider the correct diameter of the product when inflated (please see product sheet).

When inflating products without a pressure gauge, fill the fender/buoy until the walls start to expand, and make sure that you are able to depress the wall at least 1⁄2 inch (approx. 1 cm) with light hand pressure. For tropical conditions: Approx. 1 inch (1,5 cm).

Do not over-inflate as this will weaken the product and voids the warranty!

"Rules of inflation":

- - Max. 0.15 to 0.20 bar of pressure at 20° celsius.

- - In tropical conditions / high temperatures / sun: reduce to 0.05 - 0.06 bar.

- - Able to depress the wall at least 1⁄2 inch (approx. 1 cm) with light hand pressure.

- - Check the correct diameter of the product when inflated.

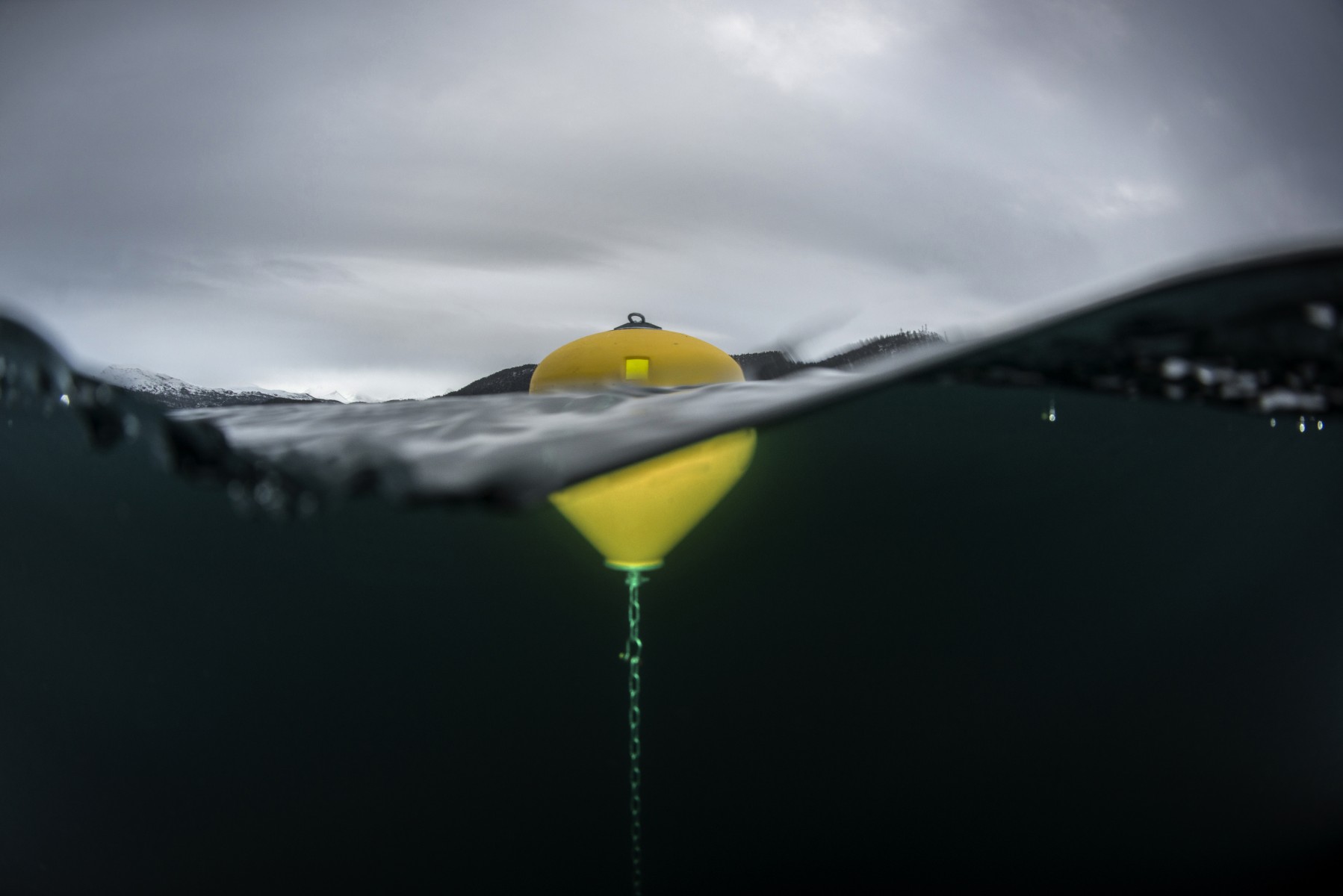

Mooring

For maximum safety we recommend that only the lower swivel (under water) is used for mooring of the boat. The upper grip ring is not for mooring.

The size of the buoy depends on the weight and the total load it will be exposed to. Do not expose the buoy to a load of more than 60% of its total buoyancy. Please also consider additional weight/load caused by marine growth, currents, wind and waves. The dimension of the mooring iron bar and swivel should be chosen in accordance with the size and weight of the boat, weather conditions, the currents and wave height in the area the mooring is intended to be placed.

Please remember to check your mooring for wear and tear at least twice a year.

To avoid extensive corrosion to the hot dipped galvanized rod and swivel, do not connect metal parts of stainless steel, aluminium, copper or brass to the rod or swivel.

See our mooring-guide here!

Fendering

Fenders are made to protect the boat, also in tough conditions. When deciding on the size and numbers of fenders, plan for the unexpected, toughest weather conditions. Consider extra fenders in addition to the “basic need”. Depending on the shape of the hull, weight of the boat etc., consider a possible mix of cylindrical and/or spherical fenders to achieve maximum protection. Please note that the fender guide only can provide guidance, the local conditions are of vital importance. If in doubt, ask for professional advise.

See our fender-guide here!

Cleaning

Boatfenders are made to withstand all the strain they are subjected to - and inevitable they will get scuffed up, develop rubber streaks and need some cleaning. We recommend to clean your fenders on a regular basis.

Polyform recommend that you talk to your local boat dealer/chandler for advice and available products. Fender cleaners, vinyl cleaners, boat shampoos or mineral spirits may be used (with reservation of content), or preferably simply soap and water. No polish needed. Note: always remember to rinse off the cleaner with lots of water.

Stronger chemicals like Lacquer Thinner or Acetone can irreversibly harm the products by breaking down the chemical composition.

Marking

Most Polyform products are highly siliconized and can be difficult to mark, but permanent marker pens with fade resistant and quick-drying ink based on alcohol, are widely used.

Scanmarin

If you are looking to replace an old Scanmarin fender or buoy, we have made a "conversion table" for you to find your corresponding POLYFORM model.

Find your model here.