Subsea

Subsea

Due to the fact that Polyform® is one of the companies in Europe with the widest range of different in-house production processes in the business, we are proud to offer a variety of solutions for Subsea applications. Our skilled engineers are dedicated to provide seamless buoyancy solutions. We possess a solid experience in the transforming of thermo-plastics, be it by rotational molding, extrusion, injection molding or a combination of the same.

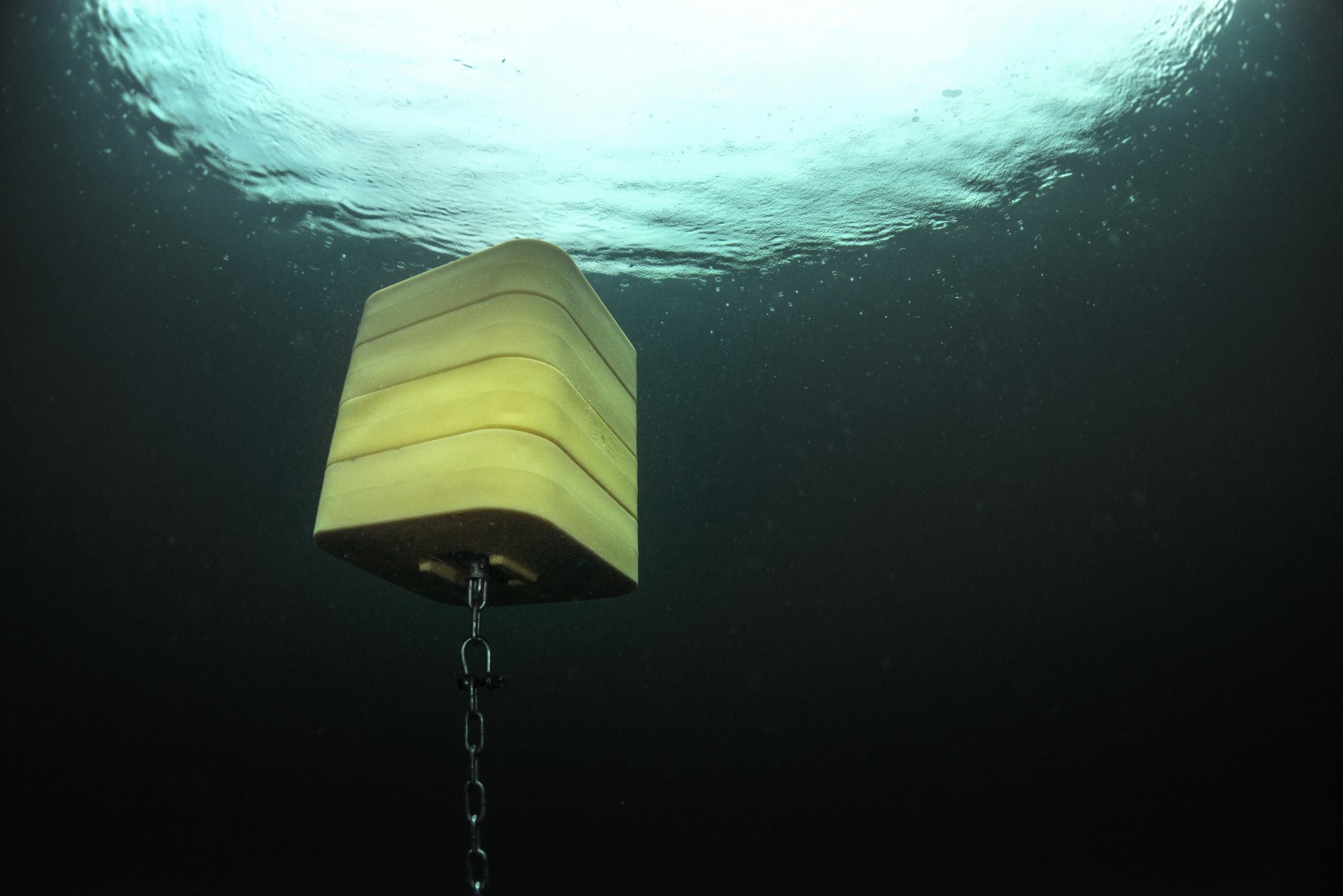

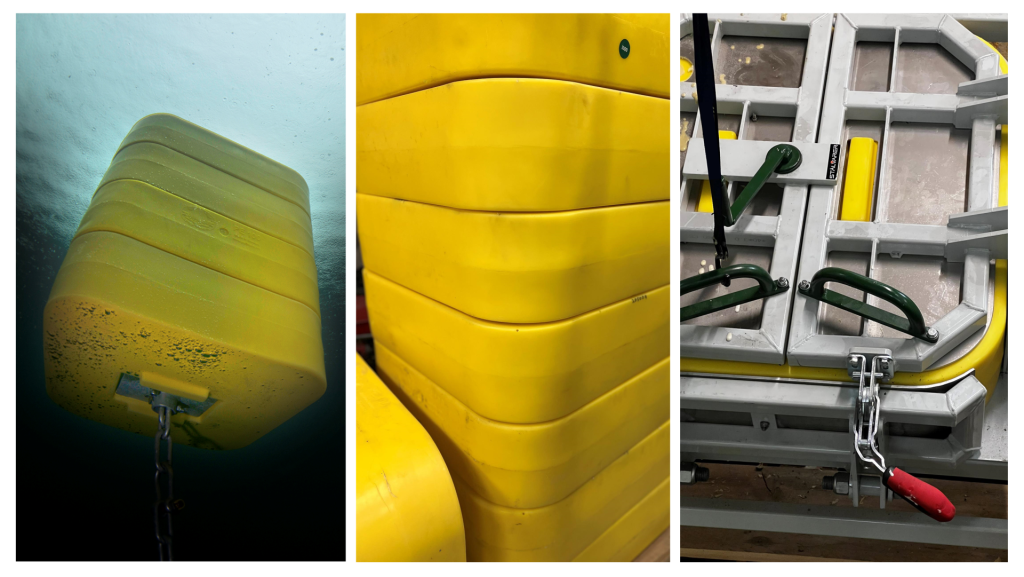

The Polyform® hard shell polyethylene (PE) products are rotationally molded buoys, proven to be a highly durable material. Buoys for subsea applications are filled with polyurethane foam (PUR), density depending on project specification and depth.

The largest type of buoys Polyform® can offer are made by assembling modular, hard shell “building blocks” – held together by use of hot dip galvanized armatures and top- and bottom plates. These large buoys are being designed and assembled individually, completely tailor made to each project.

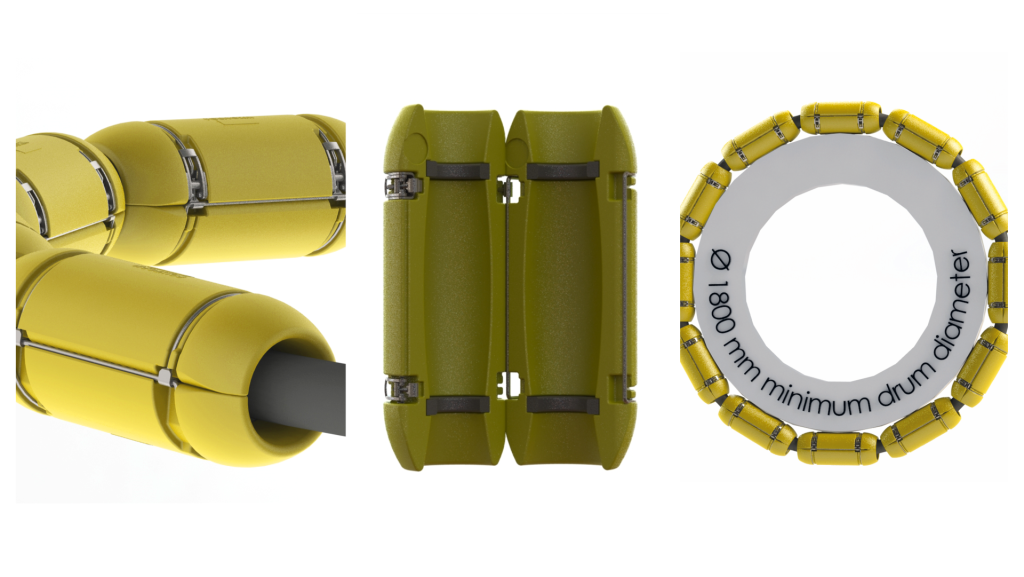

Consisting of the same core materials, we have designed the Polyform Sub Flowsafe, a hose flotation device for subsea applications. With the hard-shell exterior, interchangable inserts for different cable/hose diameters, and the unique fastening mechanism securing easy mounting and reusability. The Polyform Sub Flowsafe both deliveres buoyancy and strain relief, as well as protection to the cable/hose.

In addition to this our entire range of inflatable products can be filled with PUR foam - proving a low cost alternativ with excellent durability. Each product can be adapted to its specific purpose, enabling Polyform® to offer a wide range of solutions consisting of well-proven technologies. For more detailed information of our Buoyancy Systems, please contact us.