Environment

A different story about plastic in the sea

Polyform AS makes buoys, fenders, floats and other plastic flotation elements. All of our products are used in the sea, where they safeguard assets and help to reduce undesirable environmental impacts. Here are some examples:

Our net buoys are used by fishermen to enable them to easily find and draw their nets and lines. Without good net buoys, fishermen risk losing their equipment and catch.

The benefit to the environment is just as important. Nets that are lost become what is known as ghost nets – nets that go on to trap large numbers of fish and marine animals. Many of these nets are also made of plastic, which eventually turns into microplastics.

The fenders we produce are ‘shock absorbers’ that prevent damage when boats come into contact with other boats, and while mooring at a quay and when they are docked.

Many of these boats are made from plastic. Damage to plastic boats can be a major environmental problem and a source of microplastics. Good fendering and good fenders increase the useful life of boats and reduce one waste problem.

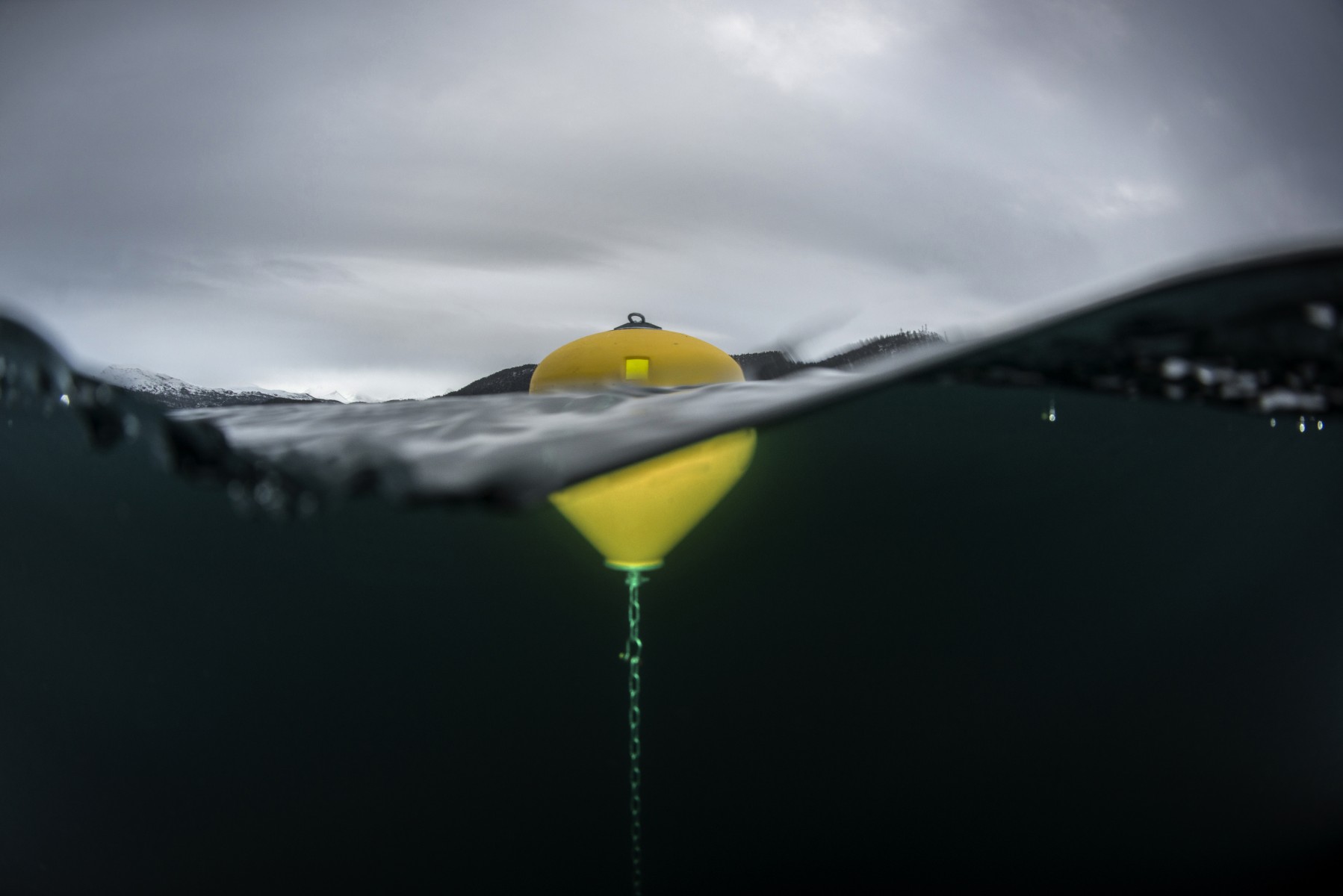

Mooring buoys are used in connection with the mooring and marking of boats, fish farms and offshore installations. Among other things, they are used offshore and in fish farming to keep expensive equipment in the right place and prevent undesirable incidents and environmental consequences. No one wants oil leakages or farmed fish escaping and breeding with wild fish.

Useful life and reuse

Polyform designs products to have a long useful life under demanding conditions. Ten to fifteen years is not uncommon. The higher the quality the fewer units that have to be produced. All of our products are suitable for material and energy recovery, and a growing number of countries are starting to facilitate such recovery. We also know that products that are taken out of service can be put into use in less demanding contexts.

What about products that are lost? This does happen from time to time. The advantage is that they float and are very visible. They can thus be picked up and brought ashore. That is if they are not found by someone who can use them. Fishermen who find a buoy will always check to see if it is in a good enough state to be used on their own boat.

But why use plastic when there is already far too much plastic in the sea?

Because quality functional plastic products are the best alternative for these kinds of flotation products. Many attempts have been made with other materials, but nothing beats plastic with respect to functionality, safety and useful life.

Environmentally responsible producer of plastic

Polyform AS complies with national and international environmental requirements. We only use approved raw materials and all our plastic is produced in-house. This gives us full control and makes it easy to document the origin and quality of the products.

All the products shall have a good environmental profile. They shall be designed to withstand the strain they are subjected to. External surfaces are produced to ensure they release a minimum of microplastics during the product’s useful life. UV resistant plastic counteracts photodegradation. If we find new, improved plastic raw ingredients, we use them if they are deemed suitable.

Continuous controls ensure that defective products are not distributed to the market – the materials are recycled.

Scraps and defective products are sent to a partner that manufactures building plastic with a useful life of 30 to 50 years, or to another form of material recovery. A small proportion goes to energy recovery and becomes district heating. Nothing goes to waste.

Transport is an important issue as our products are exported all over the world. Inflatable products are not inflated until they reach the destination where they are to be used. Other products inevitably are of a certain volume, but, on the other hand, have a low weight.

Everything can and is being improved

Environmental considerations are important in all product and process development. In that connection, as part of Ernstromgruppen, we conduct an annual environmental screening survey. Its objective is to identify points for improvement in relation to the group's strict set of values, in which ethics and environmental responsibility are important factors.

Polyform AS is an environmentally certified business pursuant to:

NS-EN ISO 9001:2015

NS-EN ISO 14001:2015

NS-ISO 45001:2018